“From Mixture to Pure: A Photostory of Simple Distillation”

For this photo story, I have chosen simple distillation, a commonly used scientific tool in various chemical experiments and big industries. In this photo story, we will go through various parts of a simple distillation column, its uses, and its functions in the distillation process.

Basically, distillation is the process of separating a mixture into its components. Simple distillation is the most simple type of distillation where components are vaporized by the application of heat and immediately condensed by cold water. This separation method works on the principle of difference in the boiling point of various chemical components. A single simple distillation unit consists of a vessel, water, beaker, condenser, insulator, etc.

Photo 1: This is what the overall setup for a simple distillation looks like.

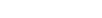

Photo 2: These are some chemicals that can be separated by simple distillation. For this, the difference between the boiling point of the two components must be greater than 40 degrees.

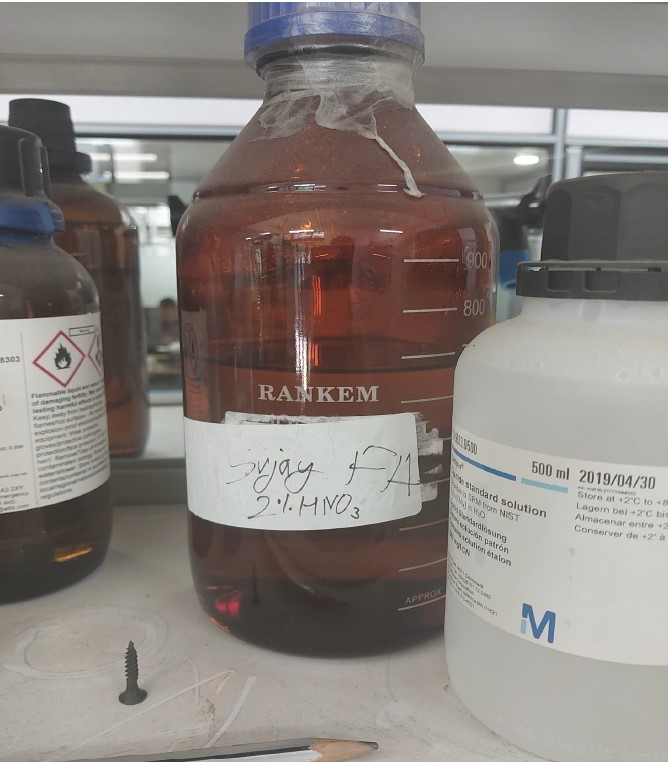

Photo 3: using measuring cylinders or beakers, we can take an accurate amount of solution for our experiment. As these instruments are made up of glass, we need to handle them safely.

Photo 4: This is a magnetic stirrer that is generally used to prepare the mixture for experiments. This instrument is made by using the magnetic field concept. The stirrer present inside this equipment rotates using a magnetic field around it.

Photo 5: This is a heating unit where the mixture gets heated above its boiling point and converted into a gaseous form.

Photo 6: The white part in the following picture is the insulation unit. This allows the user to handle it. This stops the heat flow and we can remove the cylindrical flask from inside the heating unit.

Photo 7: Now, the vaporized mixture needs to condense to convert it back into a liquid state. Here is a picture of the condenser in which the inlet contains a gaseous state and the outlet contains a liquid state.

Photo 8: for the process of condensation, we need water which acts as a coolant in process of converting gas to liquid. This is how the water gets circulated over a long glass tube. This will help in maintaining the overall temperature of the setup.

Photo 9: One of the important aspects of this setup is cooling and for that, we need a flow of coolant that can be controllable. Using this, we can change the flow rate of water. Also, we need a source of electricity for this experiment.

Photo 10: As we are using a huge amount of water to cool the gas, we need to restore it as this water is not actually getting used. For collecting this water, we need big buckets.

Simple distillation is the first invented method to separate the mixture of two or more components. Even though, the precision is less as compared to other distillation techniques, economically it is still one of the preferred techniques that industries are using. The main benefit of this method is that it is easy to control and it is a very safe distillation technique. So, as per economical and safety concerns taken into account, this is the best possible choice.

Acknowledgment: I would like to thank the chemical lab staff and TA Nitin Bhaiya for their valuable guidance and for allowing me to take the photographs.